Custom Manufacturing

Need Something Custom Made?

We Can Help

Hewitt offers many custom manufacturing processes year round. Contact us today if you need something made or fabricated. We offer Roto Molding of Polyethylene and PVC (Plasticol) parts up to 102”. CNC Bender, 3D and Roll Bending capable of bending 3” steel up to ¼”. As well as CNC Milling cable of machining parts up to 32ft long.

Industries we currently serve include Agricultural, Construction, Recreational, Marine, Medical, Manufacturing and Consumer Goods.

Custom Services Including:

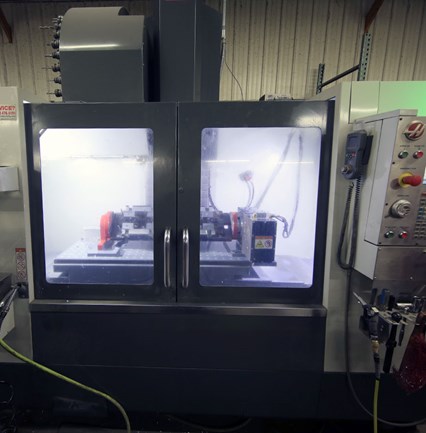

CNC Milling

We offer CNC Milling and have three Hass and one Satellite XT machines capable of machining parts up to 32ft long.

What Are The Benefits?

- Requires few steps to produce parts, resulting in high efficiency.

- The process is more precise than manual machining and can be repeated in the same manner over and over again.

- Provides the ability to produce complex shapes with a high level of precision.

- Operates with advanced software to produce outputs and multiple functions that cannot manually be replicated.

How Does It Work?

CNC milling, or computer numerical control milling, is a machining process which employs computerized controls and rotating multi-point cutting tools to progressively remove material from the workpiece and produce a custom-designed part or product. This process is suitable for machining a wide range of materials, such as metal, plastic, and producing a variety of custom-designed parts and products.

CNC Bender

We offer CNC Bending, 3D and Roll Bending capable of bending 3” steel up to ¼”.

What Are The Benefits?

With CNC-programmed guidance, each piece in your manufacturing run will mirror the next, ensuring consistency even with mass production. This results in a higher quality finished product.

How Does It Work?

CNC tube bending leverages cutting edge computer technology and high strength machinery to create custom tailored bending patterns.

Roto Molding

We offer Roto Molding of Polyethylene and PVC (Plasticol) parts up to 102”

What is Rotational Molding?

Often referred to as ‘roto molding’ rotational molding with plastisol and polyethylene used to create hollow parts like:

Items we are currently producing:

- Water, Hydraulic Tanks

- Boating bumpers

- Mooring balls

- Pet Toys

- Agriculture/Pet Feeders

- Laundry Balls

- Medical Chairs

- Shower Seats

- Dock Wheels

Rotationally molded Polyethylene / Plastisol (PVC) parts, or Inflatables, are:

- Inexpensive

- Easy to Produce

- Durable

- Virtually Indestructible

- Cost-Effective

- Resistant to UV Light Degradation, Electricity

- Inherently Fire Safe

- Excellent Insulators

- Safe and Trusted

We also have foaming capabilities if your part needs to float or just needs extra strength.